HPL

What is HPL?

HPL compact is used in many fields such as

- Bathroom partitions

- Office and bathroom doors

- kitchens

- Tablets, table tops and desks

- Office partitions in shops and companies

- Urinal dividers

- Referrals to restaurants and hotels

- Separators of dressing rooms and separators of bathrooms

- Tablets and surfaces of laboratories and hospitals units

- Lockers wheels for the gym and clubs

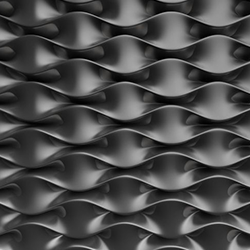

HPL compact manufacturing process

The word HPL means high pressure lamination in English, and it is an abbreviation for High Pressure Laminate, and it is the process that the HPL compact is exposed to during the manufacturing process. The manufacturing process is done by coating the layers of kraft paper on both sides with phenolic material. and moisture and collision. Then, a layer of Laminate is added to the kraft layers from the top and bottom, which is characterized by being scratch-resistant and easy to clean. The pressure process is carried out under PSI 1430 pressure and a temperature of 150 degrees Celsius. HPL compact boards can be manufactured in an infinite number of colors. And different fish, starting from 1.5 mm to 30 mm.

The HPL compact has unique features such as:

- Ease of disassembly and installation without the need for much effort

- It bears high temperatures due to its resistance to fire, and therefore it is considered a very safe material for use in industrial and commercial fields

- It is resistant to water and moisture and is therefore used in the manufacture of bathroom partitions and bathroom separators

- Its resistance to weather and sun factors, thanks to its resistance to water, heat and fire

- It is resistant to bacteria and acids, and for this reason, Compact HPL is a unique choice for use in bathroom partitions and health fields such as laboratories and hospitals.

- The HPL compact is easy to clean

- Compact HPL is completely non-toxic and non-polluting